Strapping is a material used with straps to reinforce or fasten products and goods in transportation and storage. Belts are an essential part of various industries, including packaging, transportation, agriculture, construction, timber manufacturing, and more. Each field will require a distinct type of belt for certain applications. Continue reading our article below to find honest reviews of the quality of our strapping, helping you make a better choice for your purposes.

4 popular types of strapping

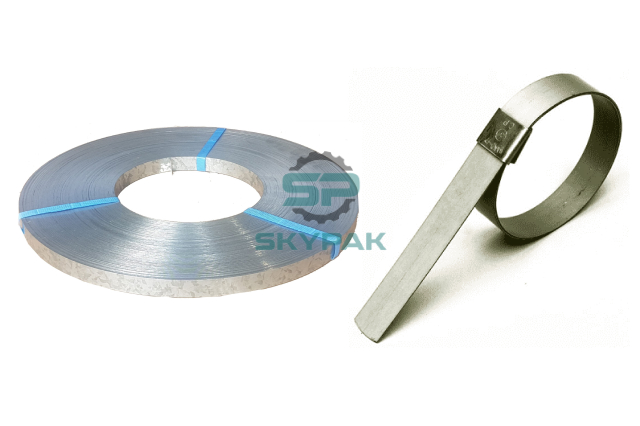

Steel straps

Steel straps provide strong support, even for the heaviest loads. Due to their strength and durability, steel straps are also a great choice if the products you are strapping have sharp corners or edges. However, steel straps can damage during transit. for soft, easy-to-grasp items Steel also has no elasticity, making it a poor choice for packaging products that can settle. Steel is also a material that is susceptible to rust, affecting the products being fixed.

Composite straps

Composite straps are made from polyester and polypropylene materials. These are 2 common materials in the production of belts. As they provide a reliable strapping solution and offer many benefits. Often used as an alternative to steel belts because of their equal strength. Besides:

- It can stretch and retract to keep your bundle secure at all times.

- It’s softer than steel, which keeps it from going into your product even when tightly bound.

- Composite straps will not rust, avoiding affecting their products.

- Strapping guarantees international quality thanks to TUV Rheinland certification

PET Plastic Straps

PET straps are featured in green color, they are used for the same applications as composite straps. However, in terms of strength and bearing capacity, PET rope is still lower than composite strapping.

PP plastic straps

PP strapping is average, with certain applications such as cargo sealing or product packaging. Plastic straps are prone to cutting and difficult to recover their stretch, so you may need to use other strapping options when transporting heavy items during transit.

Evaluation of the quality of the types of fastening straps

- Breaking Strength: Breaking strength refers to the weight the strap can hold before breaking. Steel and composite straps have comparable strength to PET and PP. PP straps have the lowest breaking strength of the four and should only be used in low-weight cases.

- Elongation: Elongation is the word used to refer to the stretchability of a strap on a group of items. Composite, PET strapping can stretch around items easily. You can achieve some degree of elongation with PP straps, but this is not recommended as the plastic can break under greater force. Steel straps have the lowest elongation of the 4 belt types.

- Elongation Recovery: Elongation recovery is the ability to return to its original shape after undergoing the stretching process of the lashing belt. Composite and PET straps have excellent elongation recovery, while PP straps tend to retain their expanded shape after the bundle settles. Steel straps have little elongation or resilience to elongation.

- Safety: Steel straps can be sharp, and sometimes dangerous to handle, especially when not wearing gloves. Composite, PET, and plastic straps are much safer thanks to softer edges and impact resistance.

- Ease of Use: Ease of use takes into account whether a beginner can handle a certain type of lanyard. The easiest straps to use are plastic and PET. Usually, the straps of these materials can be used by hand and are easily removed upon the arrival of your product. Composite and steel strapping requires additional special tools for application and removal.