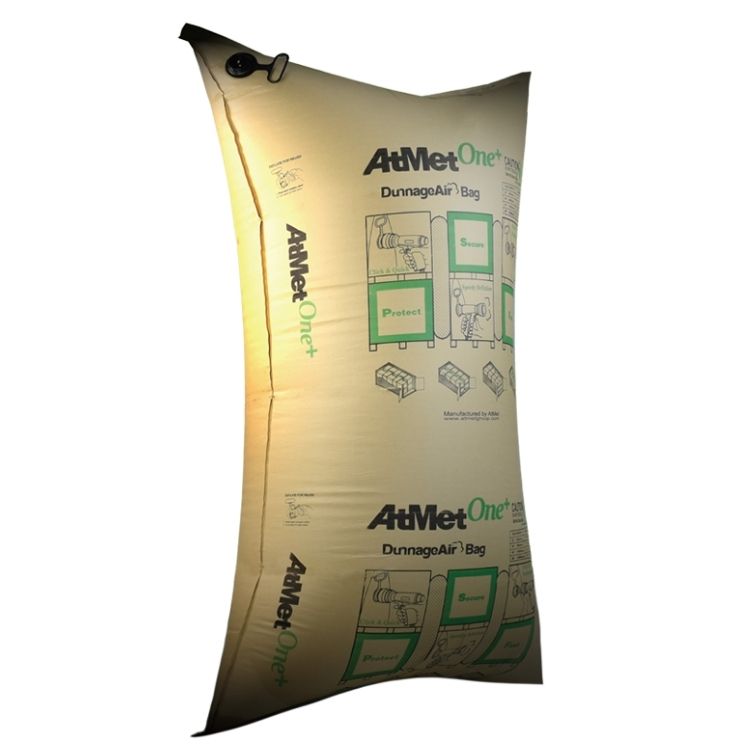

Kraft Paper Airbags

PRODUCT INFORMATION

The Kraft paper airbags are considered as a “cargo protection shield”, with excellent bearing capacity and pressure resistance. This advantage helps the product to minimize the risk of damage to the goods during transportation.

Similar to other products supporting the transportation, container airbags have their own characteristics and evaluation standards. If customers understand all of the information, they can easily make a decision of purchasing qualified products that are suitable for the businesses’ modes of transportation.

Basic information about kraft paper airbags

Classification

The airbags used in the containers are basically composed of plastic layers lined inside and covered with Kraft paper or PP Woven plastic material, with a blow valve to inflate or release air. The difference between the structure of lining layer and the outer layer divides container airbags into 2 types:

- Kraft paper airbags: the innermost is lined by the plastic layer; the middle is lined by PP Woven and the outer layer is lined by Kraft paper

- PP Airbags: inner plastic layer and outer PP Woven plastic.

Outstanding features of Kraft paper airbags

- Material used to line inner space is highly qualified, including a plastic layer helping the product to limit air release and withstand high pressure in use.

- The outer layer is covered by hard Kraft paper, which can be easily lined in the container

- It is easy to use

- They are reusable for the next transport

- The weight is so light that it is easy to store when not in use

- The outer side is made up of natural paper, which is environmentally friendly

The outer layer is made of Kraft paper, so that products can be easily lined in the container

Kraft paper airbags are more popular on Vietnamese and Chinese markets, etc. because of their outstanding advantages; however, their price will be higher than that of PP air bags.

Disadvantage of container airbags

- Outer surface is made of paper, so it is not suitable for lining wet goods or ones with high humidity

- The price is slightly higher than that of PP plastic bags

Customers can consider the given characteristics to choose the Kraft paper airbag that is suitable for their use or refer to more instructions from SKYPAK experts.

Instructions for selecting and using kraft paper airbags

Considering the characteristics of the goods, if the item is dry or fragile, the Kraft paper airbags is the perfect choice. In the case of frozen goods, it is better to choose PP air bags. View more PP container airbags

To calculate the appropriate size of the airbags, it is necessary to calculate the remaining empty space inside the container. Based on:

- Measure the length, width, and height of the package

- Measure length, height of the container

The space size is ⅓ of the airbag width, allowing the airbag to provide optimal cargo protection. Formula to calculate suitable airbag width: Space size x 3.

The airbags only have the most efficient protection when the space is 1/3 of the width of the airbag

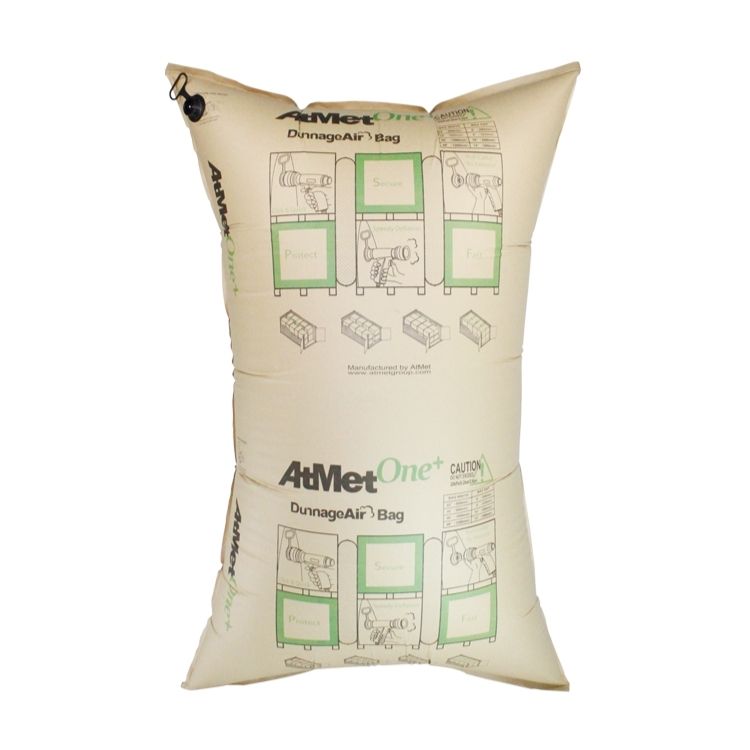

Customers can watch more videos on how to use kraft paper airbags here

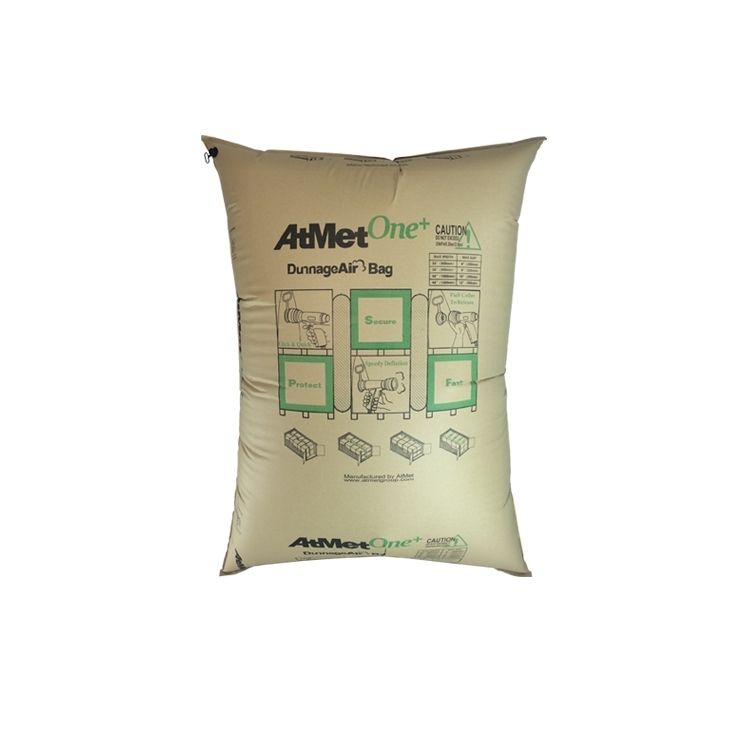

Atmet container airbags with AAR certification – USA

Outstanding advantages of Atmet airbags

Airbags are the key products of Atmet Group Inc which has the headquarter in Atlanta, USA and has multiple branches in China, Singapore, Korea, Vietnam and Thailand.

- Atmet kraft airbags have an optimal design with an inner layer made of multi-layer plastic and pressed from 4 types of plastic LDPE, HDPE, PA, PE; outstanding in the ability to limit air release and withstand high pressure in use. Additionally, there is a PP Woven lining and the outer layer is lined by Kraft paper.

- The products have good durability and meet international export standards.

- There are various sizes: 50x100cm, 60×100/120cm, 80x120cm, 100x180cm, 100x200cm, 120x240cm…

- The high elasticity protects goods optimally from the impacts during transportation

- There is a valve with a large diameter, which helps the bag to be inflated in a short time and limit gas leakage during the inflation process. Combined with a smart pumping gun which can self-adjust the amount of input air

- It is easy to use, saves time and labor costs

- International certifications: ISO 9001, SGS Test, ROHS, and the most important certification for airbags – AAR (Association of American Railroads) of the United States

New generation pump gun automatically adjusts the amount of air pumped into the product

AAR certification for the airbags

AAR is the world’s most prestigious certification issued by the Association of American Railroads. This is a mandatory certification for all suppliers who wish to join, cooperate and exchange secure shipping services worldwide.

AAR is the most important certification for airbag products. Obtaining this certification means that the products are manufactured under strict control of the Association.

The Atmet airbags achieve AAR certification, which is always appreciated for its quality and trusted in the world.

Container airbags are certified AAR and meet international export standards.

Convenient solution for customers buying Atmet airbags

SKY PAK is a distributor of Atmet airbags on the market in Vietnam, quality commitment is always a top priority.

- Offering a full service package: Quick and dedicated consultation, free samples supply and professional purchasing and delivery process

- Support consulting the right size and how to keep the product durable

- Competitive price, good discount according to purchase quantity

- 1-1 warranty for air bags with poor quality

We hope that the information about the Atmet airbags that SKY PAK has compiled, has given you an overview of the product and easily made the right choice for the needs of your business.

- Dimensions (length x width): 1800×1000 (mm), 800×1200 (mm)

- Material: PP paper (paper/polypropylene)

- Maximum inflatable thickness: 1/3 of airbag width

compressive capacity: 1600 (kg)/1m² - Valve: large valve

- Packing: 50 bags/carton

- Manufacturer: Atmet Group Inc.

- Made in China

- Quality certification: AAR, ROHS – SGS, ISO

- Storage: cool, dry place, avoid hot sun, do not contact with sharp and pointed objects