Consumers have long believed that a polyester composite strap cannot be compared with steel straps when binding heavy loads. But, is this concept still true in an age of increasingly advanced strapping materials like today? Which type of belt is really the best choice for your business? To find the answer, let’s compare the difference in characteristics and application of two types of steel and polyester composite strap in the article below.

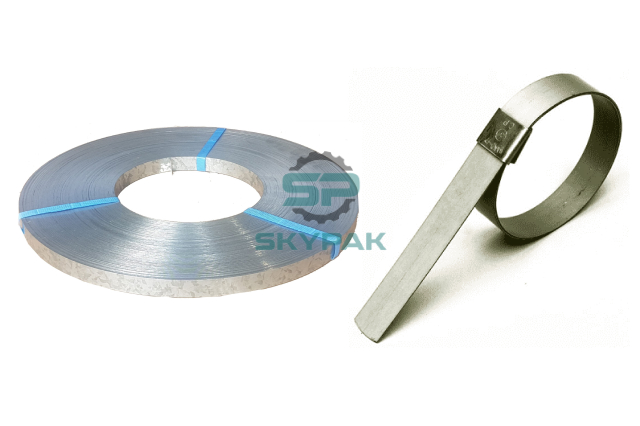

Steel straps

It is the oldest rope material and is commonly used for harsh jobs requiring heavy belts. The use of steel straps is optimal for packing industrial equipment, and heavy building materials.

What makes steel strapping strong is that it has the highest breaking strength compared to other strapping materials. Steel straps possess benefits such as large load capacity, sharp edges, high strength, and UV resistance.

Steel straps work well for holding materials that contain hard corners and sharp edges, for hot steel applications such as coils, rods, wires, etc. The use of steel also makes sense when loads are very heavy and cannot be compressed. The sturdy construction makes it best for keeping loads stable.

The wear and corrosion resistance of a steel bracelet can vary by type, grade, and usage. So be careful when strapping products with steel straps, if you don’t use the steel straps properly, steel straps can oxidize and rust and can even pass from the belt to the product.

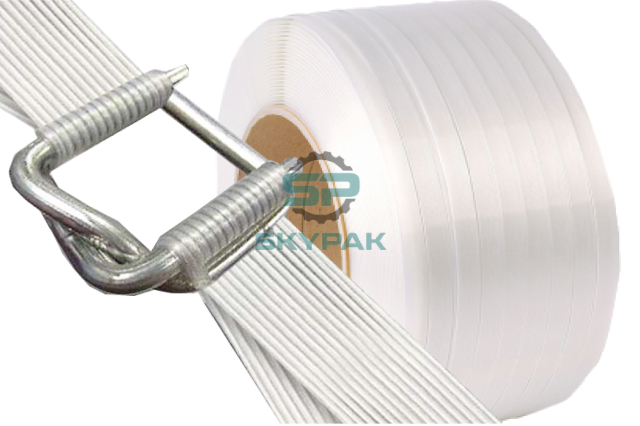

Polyester composite strap

This new strapping material offers quite a few unique benefits, making it a trusted choice for strapping in today’s market.

When compared to steel straps of the same length, the polyester composite strap is much lighter. The lighter composite straps also reduce the overall load weight. This saves space, time, and fuel for transportation.

The polyester composite strap is safer than steel strapping, Polyester material provides greater operator safety as it does not have sharp edges commonly found on steel straps. The edge of polyester straps is easy to handle, reducing cuts and damage. Furthermore, when using steel straps, the user must wear gloves to protect or prevent serious injury. But with composite fastening straps, users can directly tie the rope without using a support tool.

The overall environmental impact of polyester straps is much lower than that of steel straps. In the manufacturing process, steelmaking is a forging process that requires more energy than composite wire. In addition, the polyester composite strap is a recyclable product, which helps to reduce packaging waste and disposal costs. This cost-cutting has increased the company’s profits and reduced its impact on the environment.

The construction of the composite belt also gives it many of the same characteristics as the steel belt. The elongation property keeps the belt taut as the load expands and contracts. This feature helps composite belts absorb shocks without damaging or losing their ability to sustain a load. The polyester material is resistant to environmental factors and extreme weather, keeping the belt from weakening outdoors. Moreover, unlike steel that easily rusts when wet, stainless steel composite fasteners will not affect product quality.

In addition to the above advantages, composite belts are also trusted worldwide if they are granted the TUV RHEINLAND certificate to ensure German quality.

The obvious advantages above show that composite straps can be a perfect substitute for steel straps. And this is also the reason that many businesses today have gradually switched to using composite straps to bind goods.