Oxygen absorber packs are known as the leading product preservation solution, especially for food products. Oxygen suction packs have a variety of capacities from 15cc to over 100c. Do many people wonder if the larger the oxygen pack capacity, the more oxygen it can absorb? Our article below will clarify this issue.

What is an oxygen absorber pack? How is oxygen pack capacity expressed?

Oxygen absorber packs are used to eliminate oxygen from inside the sealed environment, creating a nitrogen environment for long-term food preservation. An oxygen absorber helps protect dry food from insect damage and ensures product quality. When the product is packaged with an oxygen absorber pack in a properly sealed and sealed container, the amount of oxygen in the package is greatly reduced. An oxygen absorber pack of the right capacity will reduce the oxygen level in the product packaging to 0.01% or less.

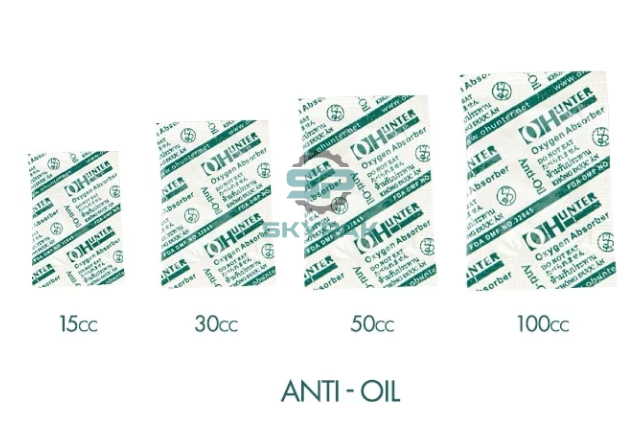

The capacity of the oxygen absorber pack is the cc number shown on the back of the product, indicating the true capacity of the oxygen absorber pack. Based on this cc number, users can choose the right oxygen absorber package for their product.

Does the larger the capacity of the oxygen absorber pack, the more oxygen it can absorb?

In the air, only about 20.8% is oxygen and 79.2% is nitrogen gas. The oxygen absorber pack only Eliminates oxygen, the remaining air in the package is mainly nitrogen, which will not affect the food or facilitate the growth of insects, and does not affect the long-term preservation of the food. Products. Therefore, not every larger oxygen absorber pack will absorb more oxygen, so you only need to Eliminate this 20.8% figure for the capacity of your product container.

In addition, the ohunter oxygen absorber pack has the special feature of being able to absorb oxygen 8 times more than the capacity indicated on the package. Therefore, it is necessary to choose oxygen pack capacity by the quality of the internal components and the quality of the packaging. Because if you choose a too-small oxygen absorber package, it will not be able to absorb the amount of oxygen inside the package, or if you choose an oxygen absorber pack with a too-large capacity, this case may cause the product box to be damaged.

To choose the right oxygen pack capacity for your product, you can do the following 2 steps:

Step 1: Calculate the volume of residual oxygen

Case 1: For gradual use (long-term) products

Amount of residual oxygen = Product capacity x 20.8% (ratio of oxygen gas)

Example: The box of beef jerky has a capacity of 500ml (equivalent to 500cc). Just multiplying this 500ml capacity by 20.8% will result in the amount of residual oxygen in the product.

500ml x 20.8% = 104ml = 104cc.

So the amount of residual oxygen in the box of dried beef is 104cc.

Case 2: For products used up in 1 time or 1 day

Amount of residual oxygen = (Total capacity – internal component capacity) x 20.8% (ratio of oxygen gas)

For example, The moon cake box has a capacity of 500ml (equivalent to 500cc), and the moon cake has a volume of 400ml (equivalent to 400cc). In this case, the residual air capacity is equal to the cake box capacity minus the cake volume. Then multiply this residual air capacity by 20.8% to get the residual oxygen capacity.

(500ml – 400ml) x 20.8% = 20.8ml = 20.8cc

So the amount of residual oxygen in the mooncake box is 20.8cc.

Step 2: Select the oxygen pack corresponding to the above capacity

The capacity of the oxygen absorber pack can reduce the following corresponding amounts of oxygen:

- 15cc – Eliminates 120cc of oxygen gas

- 30cc – Eliminates 240cc of oxygen gas

- 50cc – Eliminates 400cc of oxygen gas

- 100cc – Eliminates 800cc of oxygen gas

So if the backlog is less than 120cc, you should choose a 15cc oxygen absorber pack, and avoid choosing a 100cc oxygen suction pack, which will cause waste and strong oxygen suction can lead to product packaging distortion.

Readers can watch more detailed instruction videos here