The protective effect of the air column bags is indeed very good, but the air column bag also has some disadvantages, which is because the material for the production of the air column bag is plastic film. Although HDPE plastic film is a good, environmentally friendly plastic, it has a big disadvantage in that it is easy to be stabbed by sharp objects. Therefore, bags with air columns are also affected by this characteristic. In addition, the cushioning properties of the air column depend on the air pressure to form a cushion, preventing the packaged items from being damaged by external influences. Therefore, if during use, the airbag is hit by sharp objects, the air column bag will be damaged. With the widespread use of air column bags in industries, more and more people are beginning to understand the air column bags, but in the process of use will encounter different problems. Here, as an airbag supplier, we will exchange and share with you how to use the airbag and the notes during use.

Instructions for using the air column bags

Air column bags are used for the protective packaging of goods in many industries. For example, ceramic, glass, and electronic products are easily damaged by various impacts during transportation. Airbags are generally divided into outer packaging and inner packaging. The outer packaging is an effective way to protect fragile goods from damage. The outer packaging must have a certain compression and puncture strength, which can protect fragile goods from damage under normal conditions of transportation and storage. Inner packaging is also known as buffer packaging. The cushion packaging is mainly to fix and protect the products inside. In this case, the air column bag acts as the inner cushion packing, which can protect fragile goods from collision and vibration during transportation, making the padding protect the product in good condition.

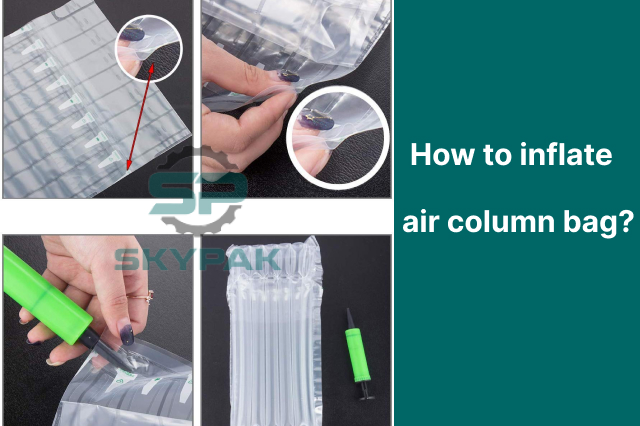

To use the column-type airbag to stomp cargo, first of all, it is necessary to choose the right size of the airbag by the quantity and characteristics of the goods: weight, size, and material… Then use it. hand-held air blower to inflate the required number of airbags. This air blower has the advantages of compactness, and simple operation, and meets the packaging needs of most users. As a result, the packaging process will take place more efficiently. Finally, line the padding, enclose the product or insert airbags into the appropriate gaps and complete the packing process.

What are the precautions when using air column bags?

Be careful when opening the outer packaging and do not scratch the inner air cushion.

When inflating the airbag, make sure that the amount of air being inflated is sufficiently pressurized to inflate the airbag. Avoid over-inflating as the airbag may burst. On the contrary, if the airbag is inflated enough, at this time, the air inside the air column bag will have a certain space to move, helping the airbag to have good elasticity, and not easy to explode. This also significantly affects the protection of the airbag.

Note, the air pump nozzle should not exceed the gas stop valve of an air column. When starting to inflate, slightly pinch the air inlet and air ducts to avoid air leaks as much as possible.

The packing area should be clean, and avoid collisions with sharp tools such as blades or nails during the use of the airbag. Place the airbag on a smooth surface to avoid contact with sharp objects that can scratch the airbag or leak air.

If the packaged items have sharp edges and corners, carton packaging should be added to the air column packaging to ensure that the packaged items are well protected.

If you used properly packaged, can provide 360 degrees of protection for each product. From the information SKYPAK shared above, hopefully, it will help customers in the process of choosing packing materials for carton goods. If you have any other questions, please contact SKYPAK for further assistance.