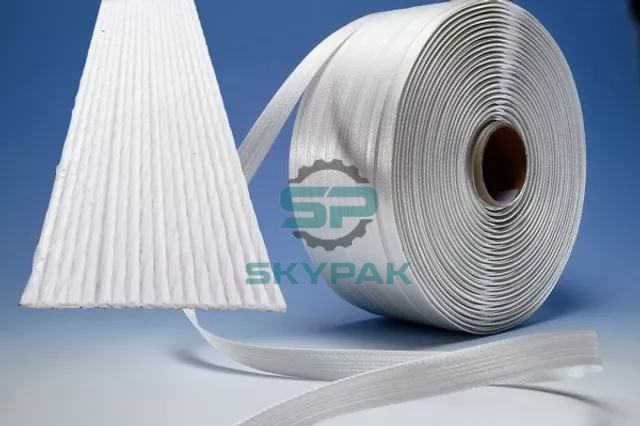

Composite strapping is a high-strength cargo binding product manufactured from polyester threads. The belt has a multi-layer construction, making it as strong as a steel belt. Therefore, composite belts are applied in many industries, including heavy industry. To know more about how composite straps are applied, please continue to follow the article below.

Why is composite strapping so popular?

Composite strapping is constructed of polyester fibers with extremely good wear resistance and strength. It is more and more widely used in place of steel belts because it is lighter in weight, corrosion resistant, and safer to use. It is also more weather resistant than steel straps. The excellent material construction allows the belt to hold products tightly without losing tension or damaging the product when strapped. In addition, composite belts are TUV Rheinland certified to ensure quality and are trusted worldwide. Composite straps are commonly used to secure medium to heavy items, providing good product reliability.

Application of composite strapping in industry

Composite strapping is widely used in the wood industry; ceramic industry, paper industry, consumer goods manufacturing industry heavy industries such as building materials production, mechanical engineering… and many other applications requiring belts. In there:

Composite strapping is used to pack steel bundles of heavily fabricated products, binding building materials such as concrete blocks, steel, wood, and glass. Materials are often transported long distances and stored for long periods of time under variable weather conditions. Therefore, if the packing belt loses tension during transportation, it will lead to conveying and product damage. Composite straps not only retain their tension over time but can also be re-tensioned if needed.

Also, unlike steel, composite straps can withstand weather conditions. This means that the product can be stored on construction sites without being damaged by the weather. Furthermore, because the composite belt is made up of stiff fibers, it can hold the load even if it is accidentally damaged by a crack or a cut.

Strapping to transport crates or pallets on containers, trucks, boats… Stabilizes and secures loads for containers in transit. Composite straps provide a secure solution. for your products in the wagon. Unlike a leash, this soft belt creates cushioning products, avoiding damage caused by shocks when the train is running. If you are shipping a product overseas, it is important to ensure it is in the container. Composite straps can be used to securely fasten a wood, glass, ceramic tiles, steel coils, and sheet materials. Composite straps are a cost-effective solution, ensuring that your items will not move during transit, no matter how rough the sea.

We hope this information is useful, helping you better understand the application of composite belts. If you have any other questions, please contact us for assistance.