Cargo strapping is the process of using strapping materials to bundle products, materials, or goods together. Belts are used primarily for industries such as transporting large industrial equipment, lumber, and reinforcement cases in distribution centers. Therefore, it is required that the material of the cargo lashing belt be ensured in terms of safety and certainty. With the development of new applications in today’s belting materials, PET Strapping is one of the great belting products, widely used in many fields, and safe for a variety of goods and services. To understand why they are so widely used, follow us in the following article.

What are PET straps?

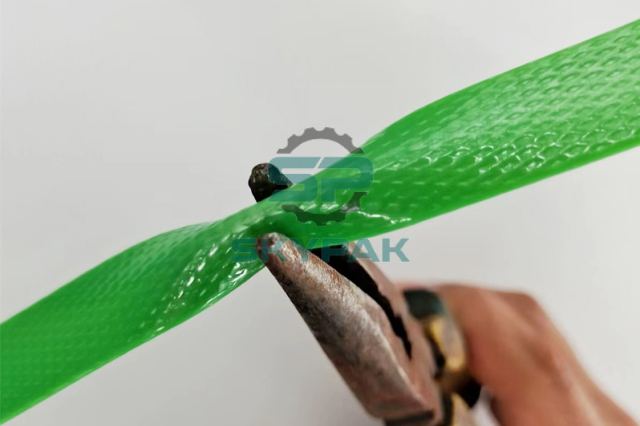

PET strapping, also called polyester straps, are manufactured from Polythene Terephthalate material, a thermoplastic, belonging to the polyester resin category. PET is one of the most durable plastic materials. It has high tensile strength and a safe working load. Belts are typically green, textured, or embossed, depending on customer needs.

PET plastic straps are used for packaging in many industries such as construction materials, pallets, household appliances, processed wood products, paper production of all kinds, etc.

Advantages of PET straps

One of the essential advantages of PET straps is to absorb shocks during transportation. They are a better alternative if you need higher initial tension to hold stiff packages than PP straps.

PET Strapping is quite durable, PET straps can hold tension longer than steel straps because they have a higher tensile strength. As a result, PET straps can adjust as the cargo contracts or expands due to pressure or changing weather conditions. Its elastic effect also helps the cargo to contract more tightly.

PET strapping is weather resistant, even with extreme weather or temperature changes, PET strapping retains its tensile strength and elastic effect.

Easy to use and handle, extremely safe, and very economical. PET strapping is light, and soft but has a pretty good strength-to-weight ratio, second only to composite straps. In addition, in terms of safety, PET belts will not cause personal injury or damage forklift tires during tensioning or cutting because PET straps do not have sharp edges.

PET straps are highly resilient and this plays an important role in securing heavy loads over a period of travel.

PET straps do not damage products, materials, or goods because in addition to being soft, without sharp edges, they do not rust like steel straps. Therefore, it does not contaminate the goods when it encounters moisture, such as rain. Therefore, PET strapping is the perfect choice for strapping bales of fabric, yarn, cotton, and the like.

While most other ropes and straps can only be used for light transport or storage applications, PET straps can be used for medium to heavy cargo strapping applications. . And while steel straps can hold heavy and bulky goods, they don’t have the elasticity and tensile strength of PET strapping. Therefore, PET strapping is a reasonable and economical alternative.