Companies that do a lot of international business are already familiar with the benefits of heat-treated pallets. These specially treated pallets are intended to eliminate insect infestation, which is required to comply with international export standards. Besides, heat-treated pallets are also less prone to wood rot and other problems due to lower humidity. Heat-treated pallets not only ensure the safety of the products being transported but also the environment at the destination of the shipment.

Why are heat-treated pallets important?

There are many ways to complete the heat treatment of wooden pallets and other wooden packaging materials, but each method typically includes three basic stages. First, the wood is thoroughly peeled. It is then placed in an enclosed space and heated to a core temperature of 56ºC for a minimum period of 30 minutes. Once completed, the pallet is stamped with a globally recognized image, allowing for more efficient transportation of goods. Heat-treated pallets can now be used for international freight. Pallets treated with this method are superior to wooden pallets for several reasons:

1. Export Compliance

The International Phytosanitary Standard for Wooden Packaging, also known as ISPM-15, requires that wooden packaging be heat-treated before being exported abroad to reduce the risk of pest contamination. These standards are established to reduce the risk of pallet contamination.

2. Reduce the load

The weight of an average wooden pallet is 15kg or more, with more durable pallets getting heavier as they use more wood. Heat treatment removes moisture from new wood and lighting pallets. Although heat treatment does not significantly reduce weight, when multiple pallets are transported at once, the weight savings can increase, resulting in lower fuel usage for large loads.

3. Reduces the risk of mold and bacteria growth

Wood is a porous material that absorbs moisture. This can make it a breeding ground for bacteria and mold. The growth of mold and bacteria on pallet surfaces can also transfer to the products the pallets transport. Heat-treated pallets make the wood more resistant to water, mold, and bacteria, reducing the risk of product contamination and eliminating the load associated with sanitation.

How to know pallet has been handled?

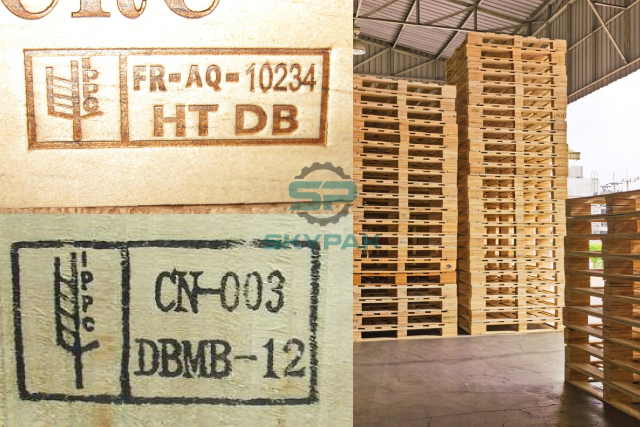

Adopted by 14 countries globally and the entire European Union, the ISPM 15 standard applies to all forms of wooden packaging. The standard requires the removal of the wooden case, treatment, fumigation, and stamping with a compliance mark. The IPPC (International Plant Protection Convention) stamp is divided into the following components:

Icon: ‘Wheat Stamp’ should be to the left of the other elements and show the IPPC mark.

Country code: The country code is the ISO (International Organization for Standardization) two-letter country code (shown below as GB). In addition, it is the unique registration number of the company applying the handling measure.

Treatment applied: Below the country code indicates the method of handling applied: DB-HT (Heat Treated Pallets) or DB-MB (Methyl Bromide Treated Pallets).