The ohunter oxygen absorber pack is often used to preserve food and pharmaceuticals. An oxygen absorber pack is useful in preventing the growth of mold and bacteria to extend the shelf life of the product by minimizing the oxygen inside the packaging. Oxygen absorber packs also ensure products do not lose their original taste and aroma prior to consumption. However, for the best use of the oxygen absorber pack, make sure to use it correctly in the ways below.

How to choose the right ohunter oxygen absorber pack

To achieve the best preservation effect, it is advisable to choose the type of oxygen absorber package and the package capacity suitable for the product to be packed. This is extremely important if you do not want your goods, food, or pharmaceutical products to be damaged due to choosing an oxygen absorber package that is not able to absorb enough oxygen, or an excessive suction type that causes the product box to distort.

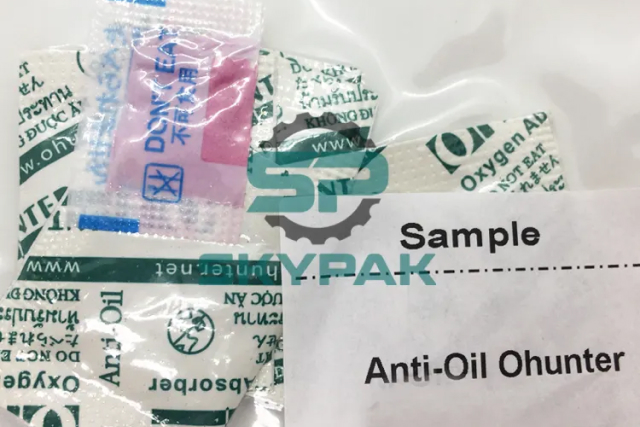

Currently, the line of ohunter oxygen absorber packs has 2 main product lines: standard and oil-proof oxygen absorbers. However, most use the oil-resistant ohunter oxygen absorber pack on the market because of their many preeminent features. Oil-resistant oxygen absorber packs in addition to reducing up to 240ml of oxygen, have excellent oil resistance thanks to the oil-resistant paper in the shell. Oil-resistant oxygen absorber packages are trusted and used by confectionery businesses. Especially the products of Pia cake, moon cake…Each anti-oil ohunter oxygen absorber pack has a pink indicator label. Help customers identify the status of the oxygen absorber pack 100% new or damaged by turning pink purple blue, meaning oxygen has penetrated.

In addition, users also need to pay attention to the capacity of the oxygen absorber package. The common capacities of the oxygen absorber pack are 15cc, 30cc, 50cc, 100cc, and 200cc… Should pay attention to the selection to match the volume and size of the product to be preserved.

If using packaging such as KOP/CPP, KOP/PE, KNY/CPP, KNY/PE, KPET/CPP, KPET/PE, Aluminum foil,… Then it is advisable to choose to package made of oxygen-blocking materials or with gas permeability below 18c.c/m2/24h. Avoid the case of choosing too thin box packaging that will dent when the oxygen pack is in, making the product unsightly.

Instructions for using the ohunter oxygen absorber pack

The ohunter oxygen absorber packs are packaged in a large vacuum bag. After opening the large vacuum bag, it is necessary to disperse and thinly spread the oxygen absorber package on the flat surface of the plastic tray, or clean, dry items. Avoid overlapping oxygen absorber packages, because the boxes can be excited, and heating occurs very quickly, which occurs because the substances inside are reacting and increasing the rate of oxygen absorption. Once fully absorbed oxygen, the oxygen absorber pack will not absorb further. Therefore, if you put the oxygen absorber in the product packaging, it will reduce or almost lose the ability to absorb oxygen.

When opening a large vacuum bag, it should be noted that within 1 hour, it is necessary to complete the removal of the oxygen absorber package inside the food packaging. Because after 1 hour, the oxygen pack will suck up oxygen from the air. Therefore, they will no longer be effective when put in the product. Besides, after opening the bag, it is necessary to manipulate the oxygen absorber packages. In particular, care should be taken to allow food to cool before packaging.

In some cases, if you do not use up all the oxygen packs after opening a large vacuum bag, you need to have a vacuum sealer and repack it immediately, after use. But when you want to vacuum packaging to preserve the oxygen absorber package, you need to make sure the packaging is clean, not get oil, water, or powder on the mouth of the bag because it may open the mouth of the bag, which is not safe. tightness guarantee.

Readers can watch more detailed instruction videos here