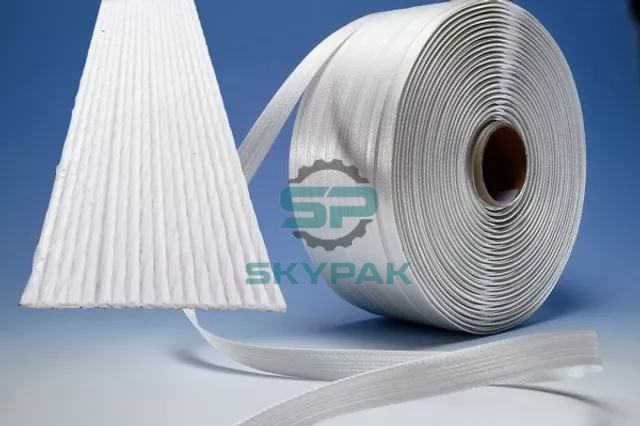

A composite belt is an indispensable item when storing, transporting, and transporting goods. Belts ensure the safety of goods, so the composite belt quality plays a very important role. Therefore, before buying, packing, and shipping goods, it is necessary to check carefully to avoid the risk of damage to the goods.

The importance of composite belt quality

Composite strapping quality is one of the most important factors in cargo binding applications. The quality of the composite belt can affect the performance, durability, and safety of the products. This also has a great impact on the cost and reputation of the business.

Quality standards include belt strength, elasticity, stiffness, and wire thickness. To ensure that composite belts meet these standards, manufacturers must perform regular quality checks.

Check the quality of composite belts

Checking the quality of composite belts is one of the most important jobs in the process of storing and transporting goods. This is one of the jobs required to ensure that your product is safe and meets quality standards.

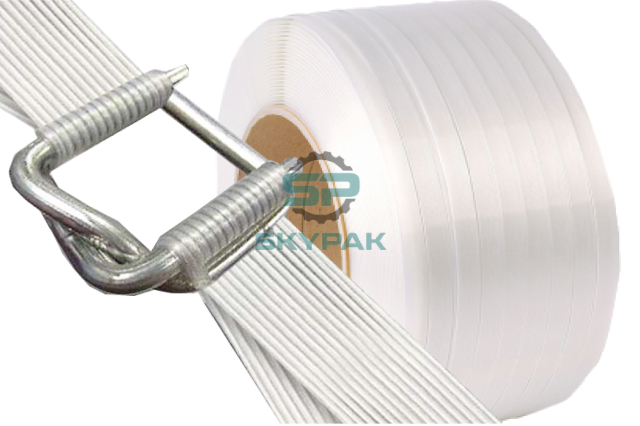

Composite belt quality testing is assessed by measuring the thickness of the belt and its stiffness. The higher the thickness of the composite belt, the higher the strength. The stiffness of the composite belt also affects the strength of the rope. The higher the stiffness, the higher the strength of the belt.

Measure the thickness of the belt

The belt thickness shall be to the accuracy specified in the quality standard. Usually, composite belts have standard thicknesses of 13mm, 16mm, 19mm, 25mm, and 32mm.

Measure the stiffness of the belt

Measuring belt stiffness is one of the most important factors in ensuring the safety of belt use. Strap stiffness is measured using a belt durometer. To measure the stiffness of the composite belt, the user needs to place a piece of the composite belt on a fixed surface. The composite belt stiffness tester is then placed on the composite belt. The device measures the stiffness of the composite belt by applying a fixed force on the composite belt. After force is applied, the device measures the stiffness of the belt and displays the result on the screen.

The higher the stiffness of the composite belt, the better the quality of the composite belt.

Measure the elasticity of the belt

The elasticity of a composite belt is determined by the belt’s ability to recover to its original shape after it has been compressed or stretched. The elasticity of a composite belt is measured by measuring the length of the belt before and after it has been compressed or stretched.

The higher the elasticity of a composite belt, the more likely the belt is to recover to its original shape after it has been compressed or stretched. The higher the elasticity of a composite belt, the greater the ability of the belt to withstand tensile forces.

The higher the elasticity of the composite belt, the greater the tension the belt can withstand and can be used in applications where high strength is required.

The strength of composite belts depends on various factors such as thickness, stiffness, noise level, elasticity, and others. Therefore, when choosing composite straps, you need to evaluate these factors to ensure that you will get a highly durable product

Follow how to use composite straps in detail here.