PET strap roll and PP plastic straps are two commonly used strapping products today. This is a familiar tool that helps the process of transporting goods and machines go smoothly and quickly. There are many types on the market today. Typical for low to high-load items are PET straps and PP straps. Each type has its own properties, application areas, and advantages and disadvantages. Therefore, to help you have more information choose the right type of traps for your needs. Let’s find out the article below!

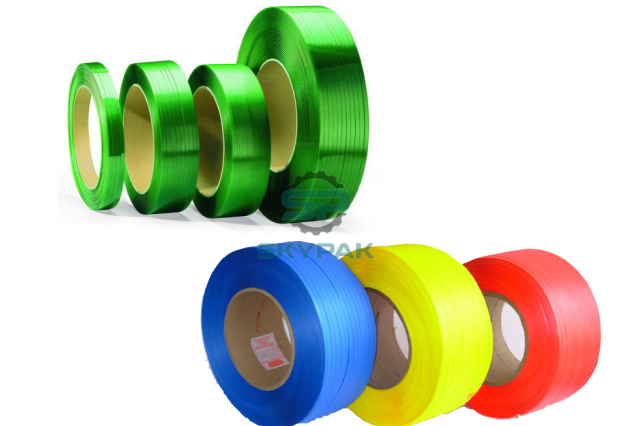

2 types of PET strap roll and PP plastic straps

Strapping is designed for jobs that require heavy-duty belting, where high strength and minimal stretch are required. In addition to composite straps, PET straps or PP straps are quite common and are used in many industries.

PET Strap roll

PET straps are the 2nd strongest plastic strapping after composite straps and stronger than PP straps. They are often used for heavy loads requiring high tension. In many industries, PET can be used as a substitute for steel. PET wire has the characteristics of green, embossed, or plain depending on customer requirements. Their high strength properties and good strength are due to the fact that they are composed of a thermoplastic PolyEthylene Terephthalate, a polyester resin. They can withstand temperatures up to 200 degrees Celsius or even -90 degrees Celsius, while the chemical structure of the belt remains unchanged.

PP Straps

PP straps have been specially designed for light to medium loads and are great in cases where goods are packed in cartons. The feature that distinguishes PP plastic straps from green PET straps and composite straps, is that they have many colors, which is more convenient for classifying packages. Therefore, they are applied to many areas of life.

What is the difference between PET strap rolls and PP plastic straps?

The main component of PP strapping is polypropylene raw material, and the main component of PET strapping is a polyester resin.

PP straps are suitable for carton packaging or lighter items. PET straps are suitable for packing large and heavy materials such as glass, steel, stone, and brick, and are more suitable for long-distance transportation.

The impact resistance and repeat bending performance of PET straps are many times stronger than those of PP plastic straps. PET straps can be stretched up to 50% more than comparable-sized PP straps.

PET straps are more durable than PP straps of the same size.

PET straps will not stretch or elongate like PP straps.

PET straps have higher temperature resistance than PP plastic straps. At the same time, PET straps will not break like PP straps when over-tightened.

Since the advantages are far superior to PP plastic straps, the price of PET straps is also much higher than that of PP plastic straps.

Belts are often used a lot in life, but many people do not know how to distinguish these 2 types of packing straps. Hopefully, the information we shared above, will be of some help to readers when choosing cargo straps. If you have any questions or need more information, please feel free to contact us for assistance.