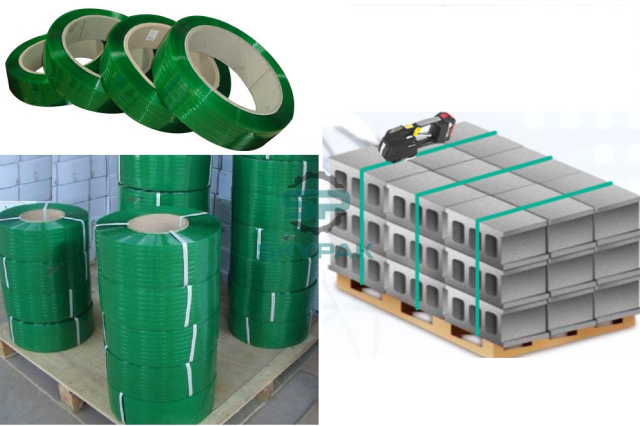

There are many stories about choosing the wrong industrial belt. When these mistakes are made, belting efficiency can become messy and costly. When tying is not successful, costs are incurred in the form of time, money, and sometimes injury. In general, they cause quite a bit of a hindrance for all involved. Let’s also explore the 3 factors below to prevent mistakes in choosing a plastic PET Strap for packaging.

Cargo load

Cargo straps depend on the load you need to strap. If you are planning to transport a large amount of construction material then a polyester PET strap is the best way to choose strapping. Such a shipment would be too heavy for a PP strapping. A real-life example of inadequate strapping is a company that uses PP straps for beer shipments instead of a plastic PET Strap or composite strap. Then some straps were stretched and broken, the stele was toppled and destroyed. The only thing that can be gained from this story is not to use PP lanyards if your cargo exceeds the required tension!

One of the most common strapping mistakes is using PP straps for premium products. PP plastic straps are quite popular because they are relatively cheap and easy to use, but they can easily break when subjected to too much pressure. Although the cheap price of PP plastic straps is certainly beneficial, using PP ropes just because of their cost is a huge and disastrous mistake.

While PP strapping is perfect for transporting lighter loads at a much lower cost, it doesn’t perform so well when handling a heavy load for long periods of time. This is because its tensile strength is much lower than that of a plastic PET Strap or composite strap, which means it simply won’t be strong enough for long enough. If you are going to use PP straps, make sure your payload is the right size and weight.

Under pressure

The plastic PET Strap is quite flexible and can be used for most light and heavy loads with no problem. It strikes an excellent balance between elasticity and strength, with high tensile strength. This is a much safer alternative to steel strapping. Tears caused by removing and installing steel belts are quite common in warehouses. A plastic PET Strap eliminates these concerns, is very durable lightweight, and costs much less than steel.

Steel straps are still the first choice for goods with sharp edges. If you are deciding between using PET or steel straps, remember to consider the weight, size, shape, and material of your cargo. If you are dealing with coils, spools, or other ferrous objects, steel belts should be used. For the remaining goods that are easily moved during transportation, it is recommended to use PET plastic straps or preferably composite straps. The PET strap has elastic properties that allow it to conform to the shape of the cargo when it is moved. Steel straps, on the other hand, are stiff and won’t move with your cargo. This is fine when handling extremely heavy and solid materials such as metal and stone, but is not ideal when holding many easily moved objects together. A stack of planks, for example, will naturally slide against each other and must be held together with a flexible material such as PET straps. Steel straps may be stiff enough to support the weight of the board, but straps are not flexible and will break when piled up from a ramp.

Weather conditions

Weather is another factor that gets overlooked when it comes to loading blocking. A plastic PET Strap performs well after long periods of exposure to UV light or extreme temperatures. On the other hand, it is moisture resistant and will not rot or corrode in stormy conditions like steel. Steel is a sturdy material that won’t deform, but it won’t withstand the onslaught of rain for a long time. Furthermore, lumber is porous and can swell when exposed to large amounts of water. The steel cannot change its shape to match the size of the PET plastic strapping wood. In this case, you should use a PET plastic strap.

The bottom line when you’re considering what type of belt to use is how flexible and tough you need it to be. PP strapping is a lot cheaper and should be used to pack or seal lighter goods that require lower tensile strength, such as bundles of newspaper. PET strapping is used for cargo requiring heavy strength and flexibility, and steel should be used for the heaviest loads with sharp corners that do not allow displacement.

It is important to consider external factors such as weather and other potential bumps on the road. One thing’s for sure, you don’t want to make the same tying mistakes! Think ahead and consider all the possibilities of straps to safely, efficiently, and affordably store your goods!